Insert molding: process, applications, and benefits

Insert molding—sometimes called insert injection molding—is a highly specialized plastic injection molding process that integrates additional components or materials within a plastic part. It involves inserting a pre-formed component, often metal or another type of substrate, into the mold cavity before the molten plastic is injected. When the molten plastic enters the cavity, it encapsulates the insert to create a solid, unified component upon cooling. Insert molding enhances the mechanical properties, functionality, and aesthetics of the final product, making it a preferred choice across various industries. Let’s dig deeper to better understand the process, benefits/disadvantages, and applications of insert molding.

The insert molding process

Since insert molding is essentially an add-on to injection molding, the process is similar; however, the insert must be considered from the outset of the design process to ensure a successful outcome:

Designing the mold. The first step in the insert molding process is designing a mold that accommodates both the plastic and the insert. Engineers must consider the insert's shape, size, and material to ensure it fits precisely within the mold cavity. This step is crucial to prevent misalignment and achieve optimal bonding between the plastic and the insert.

Preparing the insert. The insert, often made from metal or other robust materials, must be thoroughly cleaned and, if necessary, pre-heated. Cleaning removes any contaminants that could interfere with the bonding process, while pre-heating ensures the insert doesn’t cool the injected plastic too quickly, which could lead to incomplete filling or weak bonding.

Placing the insert in the mold. The prepared insert is placed into the mold cavity. This can be done manually or using automation, depending on the production scale and precision required. The insert must be held securely in place to prevent movement during the injection of the plastic.

Injection molding. With the insert in place, the mold is closed and molten plastic is injected into the cavity. The plastic flows around the insert, filling the mold completely. The injection parameters, such as pressure, temperature, and injection speed, must be carefully controlled to ensure uniform filling and proper encapsulation of the insert.

Cooling. Once the cavity is filled, the mold is cooled to solidify the plastic. Cooling time varies depending on the plastic material and the thickness of the part. As with all plastic injection molding, effective cooling is essential to achieve the desired mechanical properties and to prevent defects such as warping or shrinkage.

Ejection. After the plastic has sufficiently cooled and solidified, the mold opens and the finished part is ejected. The ejection mechanism must be designed to handle the part delicately to avoid damage, especially if the insert is a critical functional component.

Quality inspection. The final step involves inspecting the molded part to ensure it meets all specifications and quality standards. This includes checking the alignment of the insert, the integrity of the plastic encapsulation, and any dimensional tolerances. Advanced inspection techniques, such as X-ray or ultrasonic testing, may be used to verify the internal bonding and structure.

Materials considerations

Material selection is particularly important in insert injection molding to achieve the desired mechanical properties and functionality of the final product. Commonly used plastic resins include thermoplastics like polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC). Check out our plastic injection molding material selection guide for more information about these materials). Thermosetting plastics, such as epoxy and phenolic resins, are also used when high heat resistance and dimensional stability are required. The inserts themselves are often made from metals like stainless steel, brass, aluminum, and copper, which provide the necessary strength, conductivity, and durability. Non-metal inserts, such as ceramic, glass, and composites, are used for specialized applications that demand unique properties like insulation or corrosion resistance.

Material compatibility significantly impacts the outcome of the insert molding process. The thermal expansion coefficients of the plastic and the insert must be compatible to prevent stress and warping during cooling. The bonding properties between the plastic and the insert are also critical; poor adhesion can lead to delamination or weak structural integrity. Chemical compatibility is another important factor, as certain plastics can react with metals or other inserts, leading to degradation or failure of the part. Engineers must carefully select materials that not only meet the functional requirements of the final product but also work harmoniously together during the molding process to ensure a high-quality and reliable outcome.

Insert molding technologies and machinery

Because insert molding is a highly complex and precise process, it requires specialized equipment and technologies. Here are some examples:

- Insert molding demands stringent control over injection parameters, such as pressure, temperature, and injection speed. Specialized injection molding machines are equipped with advanced control systems that allow for precise adjustment and monitoring of these parameters. This control is crucial to ensure uniform filling, minimizing defects, and achieving strong bonding between the plastic and the insert.

- Robotic systems are often employed with insert molding machines to place inserts into molds with high precision and consistency. Robotic arms and automated placement devices ensure consistent and accurate positioning of inserts, reducing cycle times and improving repeatability, ideal for high volume production This automation is particularly important for maintaining high production efficiency and reducing labor costs.

- As mentioned above, a highly precise mold is required to accommodate both the plastic and the insert materials. These molds are designed to achieve tight tolerances and complex geometries, as they must support the insert securely and allow the molten plastic to flow and encapsulate the insert properly. Specialized molds can include multi-cavity setups, precision alignment features, and advanced gating systems to manage the flow of plastic around the insert. Specialized hot runner systems maintain the plastic in a molten state within the mold, reducing waste and improving cycle times.

- Also noted above, effective cooling is essential to solidify the plastic around the insert properly. Specialized cooling equipment often includes advanced cooling systems that can be tailored to the specific requirements of the insert and plastic materials, ensuring optimal cooling rates and preventing defects such as warping.

- Enhanced ejection systems are also required to remove the finished product without damaging the insert or the surrounding plastic. Specialized equipment includes carefully designed ejection mechanisms that can handle delicate and complex parts, ensuring smooth and damage-free ejection.

These specialized features collectively ensure the production of high-quality, reliable parts with the desired mechanical properties and functionality.

Insert molding advantages and disadvantages

Insert injection molding offers several advantages that make it an attractive manufacturing process for many applications. One of the primary benefits is enhanced mechanical properties: By combining the properties of plastic and metal or other materials, insert molding can significantly improve the mechanical strength and durability of a part. This integration often results in parts that are stronger and more robust than those made from a single material. Additionally, insert molding reduces assembly costs by integrating components during the molding process; since the additional components are already encapsulated in the product during injection molding, there isn’t a need for secondary assembly operations. This reduction in assembly steps not only cuts labor costs but also minimizes the potential for assembly errors, leading to more reliable and consistent products. This also allows for improved functionality, enabling the creation of complex, multi-material components that provide enhanced features, such as better electrical conductivity, heat dissipation, or wear resistance. Additionally, insert molding offers significant design flexibility, allowing for the production of intricate and detailed parts that would be challenging or impossible to produce using traditional manufacturing methods. This flexibility opens up new possibilities for innovative product designs and applications.

Insert injection molding offers several advantages that make it an attractive manufacturing process for many applications. One of the primary benefits is enhanced mechanical properties: By combining the properties of plastic and metal or other materials, insert molding can significantly improve the mechanical strength and durability of a part. This integration often results in parts that are stronger and more robust than those made from a single material. Additionally, insert molding reduces assembly costs by integrating components during the molding process; since the additional components are already encapsulated in the product during injection molding, there isn’t a need for secondary assembly operations. This reduction in assembly steps not only cuts labor costs but also minimizes the potential for assembly errors, leading to more reliable and consistent products. This also allows for improved functionality, enabling the creation of complex, multi-material components that provide enhanced features, such as better electrical conductivity, heat dissipation, or wear resistance. Additionally, insert molding offers significant design flexibility, allowing for the production of intricate and detailed parts that would be challenging or impossible to produce using traditional manufacturing methods. This flexibility opens up new possibilities for innovative product designs and applications.

Despite its many advantages, insert molding also has some disadvantages that must be considered. One of the main drawbacks is the higher initial costs associated with designing and manufacturing molds for insert molding. The added complexity of the process requires more sophisticated and expensive mold designs compared to standard injection molding, which can increase the upfront investment. Additionally, setting up for insert molding, especially for complex or high-precision parts, can take longer, potentially increasing lead times for new projects. This can be a critical factor for time-sensitive production schedules. Material compatibility issues also pose a significant challenge in insert molding. Ensuring that the plastic and insert materials are compatible in terms of thermal expansion, bonding properties, and chemical resistance is essential to avoid defects. Differences in these properties must be carefully managed to achieve a high-quality final product, adding another layer of complexity to the process.

Applications

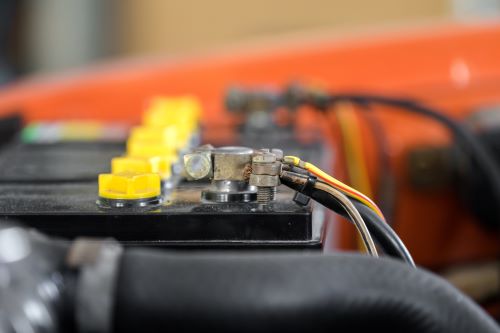

Considering its pros and cons, a number of industries have adopted insert molding as a preferred production method. In the automotive industry, insert molding is used to produce components that require high strength and thermal resistance, such as engine covers and housings that incorporate metal inserts for added durability. Electrical connectors and switches in vehicles often use insert molding to encapsulate metal terminals within a plastic housing, ensuring secure connections and resistance to environmental factors.

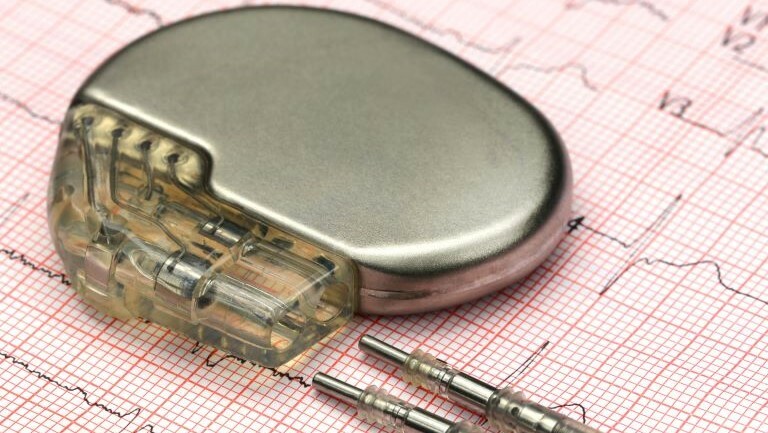

In the medical field, insert molding enables the production of surgical instruments with metal tips and plastic handles, combining the strength and precision of metal with the ergonomic benefits of plastic. Medical implants, such as pacemakers and orthopedic devices, often use insert molding to encase electronic components or metal supports within a biocompatible plastic.

Other applications of insert molding can be found across consumer electronics. Smartphone components like buttons and connectors, which require precise alignment and robust construction to ensure reliability and performance, are often created by insert molding. Wearables, such as fitness trackers and smartwatches, integrate electronic components within a durable, lightweight plastic housing.

A number of your household appliances likely include insert molded features. For example, insert molding produces durable handles and knobs by integrating metal reinforcement within a plastic exterior, enhancing strength and aesthetic appeal. Power switches, plugs, and sockets often use insert molding to combine metal conductors with plastic insulation, ensuring safety and functionality.

In industrial applications, sensors and actuators use insert molding to encapsulate sensitive electronic components, providing protection from harsh environments while maintaining performance. Custom tooling and fixtures for manufacturing processes can be produced using insert molding to integrate metal wear surfaces within a plastic structure, enhancing longevity and reducing weight.

Finally, aerospace components, such as brackets and mounts, benefit from insert molding by combining the strength of metal inserts with the lightweight properties of advanced plastics. Aerospace connectors often require insert molding to ensure reliable performance under extreme conditions, integrating metal contacts within a high-strength plastic housing.

Selecting an insert molding partner

As we’ve seen in this post, insert molding is a versatile and highly effective manufacturing process that offers numerous benefits. Because of the many nuances of the process, it’s critical to find a partner with the necessary expertise, equipment, and capabilities to achieve successful insert injection molding. Nelson Miller Group has domestic plastics experience dating back to the 1950s and regularly leverages insert molding to produce complex, multi-material components. We’re additionally known as subject matter experts on the evaluation, selection, and processing of a broad range of thermoplastic resins and can help you select the right materials for your next insert molding project.

About NMG

NMG has more than 85 years of experience partnering with organizations to bring their industrial, IoT, lighting, medical, telecommunications, consumer, and aerospace products to life. We solve your most complex challenges in engineering design, manufacturing, and supply chain management.

Follow NMG

Could your company use results like this?

We want to learn about your organization and understand your unique challenges.